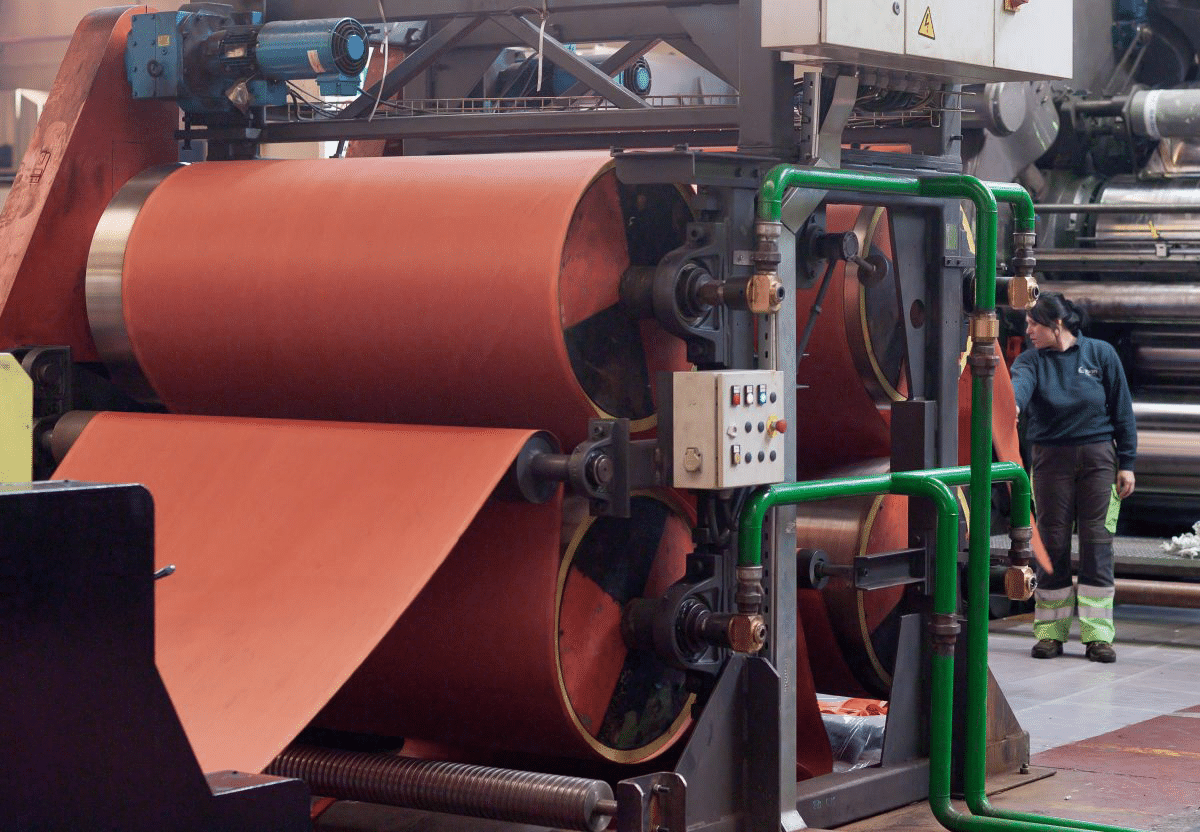

At SIBAN, thanks to our innovative spirit and commitment to continuous improvement, we have developed the SRC-35 (Abrasion Special Compound) belt.

The use of this polymer layer applied to the conveyor belt establishes a new product family that will develop this sector in a very important way. The physical and mechanical properties of the product represent an unprecedented development for conveyor belt cover properties for the toughest applications.

Characteristics such as the abrasion level, tensile strength and elongation at break are increased to levels beyond those that can be achieved with any type of rubber. These properties allow thinner belts to be used than a standard rubber equivalent whilst improving belt lifetime and offers considerable energy potential.

The SRC-35 covers can be applied to just one cover or to both top and bottom covers. Belt dimensions are calculated and matched to the requirements of the service load, demands of the installation and client request.

The manufactoring of belts with SRC-35 is developed according to the application requirements. The belt carcass is usually a standard construction, or can follow the design of the Cushion Belt. These belts are also resistant to grease and oil and are suitable for transporting FDA-approved food materials