BELTSIFLEX® introduces the production of a new type of fabric used in the construction of conveyor belts, known as Straight Warp — a new concept for rubber belts.

Hard-Woven belts are made with this new Straight Warp fabric and offer numerous advantages over conventional EP fabric belts, delivering high performance in applications where there is a risk of breakage and cuts.

These belts offer several advantages compared to others:

-

Resistant under conditions of heavy impact, generally in extreme transport environments.

-

Significantly longer belt lifespan compared to traditional belts.

-

The scalloped (sawtooth) splice system provides greater flexibility and better drum adaptability.

-

Greater durability than the traditional stepped splice system.

-

Cost savings due to reduced installation time.

These belts are manufactured in two different series:

-

Single-ply Hard-Woven: Built with a single fabric layer, available in strengths HW500, HW630, and HW800.

-

Double-ply Hard-Woven: Built with two fabric layers, available in strengths HW1000, HW1250, and HW1600.

On the other hand, Aramid Belts, developed by SIBAN, have proven to be the ideal alternative with a number of significant advantages, offering the same levels of resistance as steel cord belts, but with up to five times less weight, resulting in reduced electricity consumption for the installation, as well as lower wear on drums and drive systems.

Single-ply Aramid belt: With a single fabric with strengths of HA630, HA800, HA1000, HA1250, HA1400, HA1600 and HA1800.

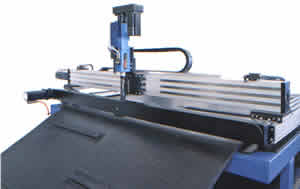

Belts for shot blasting machines with guiding and drag profiles. They are perforated with drainage holes and built according to the specific design of the machines.

Belts for shot blasting machines with guiding and drag profiles. They are perforated with drainage holes and built according to the specific design of the machines.